Before diving into why freight shipping rates have increased by 300% recently, here’s a quick brief of what freight shipping means for those of you that aren’t familiar with the term: Freight shipping is the process of transporting commodities, goods, or cargo by land, sea, or air. The term originally exclusively meant shipping transport by sea, but it has now been extended to refer to transport by land or air also.

If you’re a business owner or a supplier, you may have noticed the increase in freight rates almost immediately. Now, you’re probably looking for answers to why these freight rates have been skyrocketing so dramatically because it’s been affecting your business. After all, if you want to think of ways to alleviate the situation, you must first understand the why.

Here’s the breakdown of the answers you’ve been looking for:

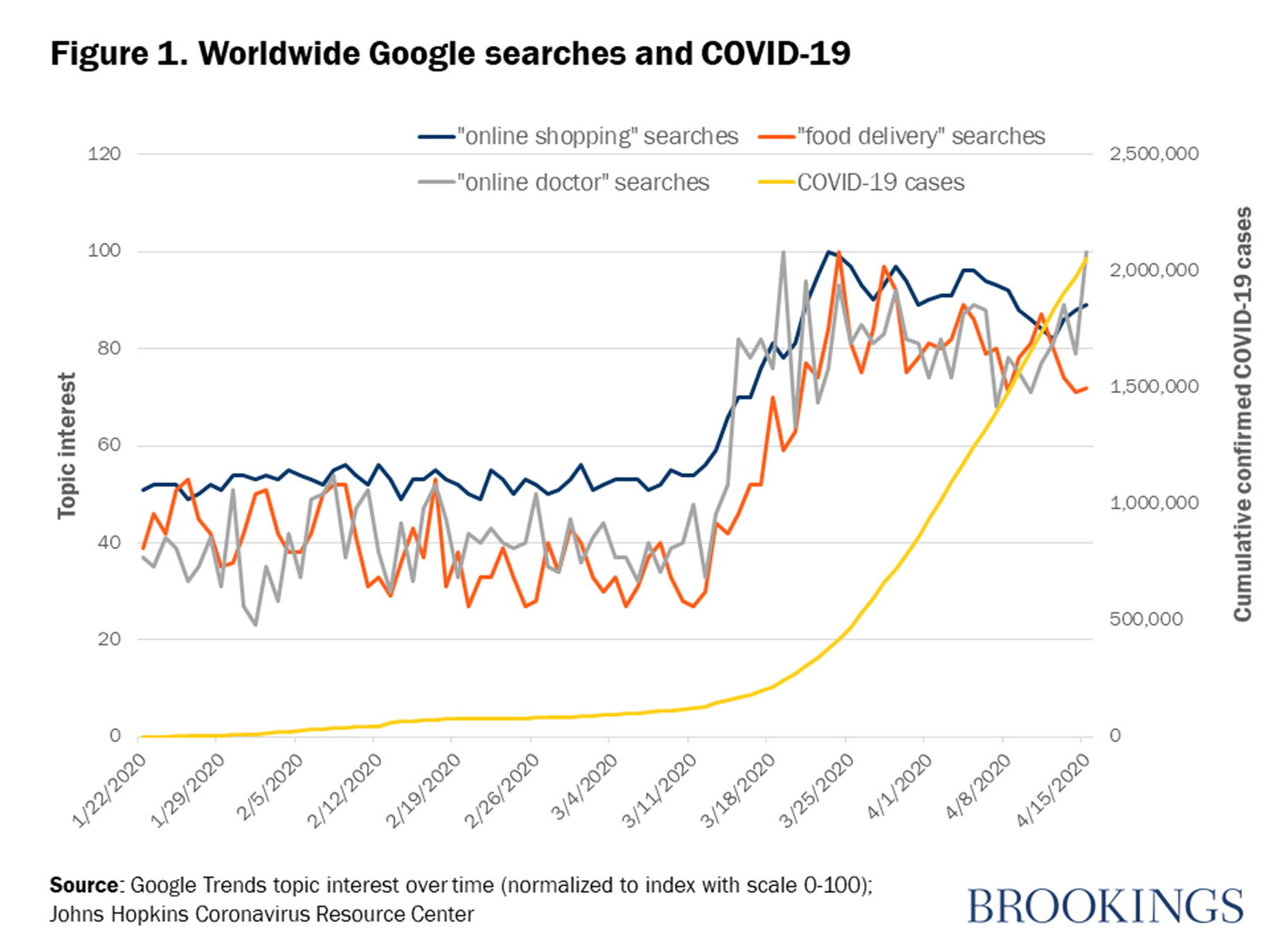

1. COVID-19

When Covid-19 first broke out, China went into lockdown, then soon later the rest of the world ensued. This lockdown had a direct impact on freight shipping because many factories and plants were shut down. Limited cargo planes and sea freights were delivering commodities because most bookings were cancelled.

2. Imbalance of Supply vs. Demand

The Covid-19 lockdown caused a shift in consumer behavior. Due to store closures and people’s fear of contracting the Coronavirus in public, they turned to online shopping. The percent of people ordering items online thus increased by 32.4% in 2020 and have gone up to 39% by 2021. This has caused a large imbalance between supply and demand because there are greater demand for items to be delivered, yet airfreight capacity is drastically lower. Typically, air freight companies will use the extra capacity at the belly of a passenger plane. Since travel restrictions have been placed and people have not been traveling as much, there’s just been fewer passenger flights. This results in less air service. To exacerbate the issue, an estimated 5.5% of all ocean capacity has been waiting outside a port. There is limited storage space for finished goods that are waiting to be shipped.

3. Storage Container Shortage

Shipping container costs have more than doubled to ship from China to the United States. This is causing an issue for companies in the US that are trying to sell their goods to Asia or other parts of the world. To better understand the current container crisis, let’s shift the world back to a normal day before this crisis began:

In a normal year, it would cost around $1500-$2500 to rent containers to ship goods from China to the west or east coast of US ports. The container would then pick up soybeans or bourbon in the US, and then it would be exported back to China or other parts of the world. However, demand from China has been incredibly high; we’ve been buying an exuberant amount of items from China that the container costs are now $4000-$6000. Therefore, shipping companies are benefiting from this large profit so much that they’d rather ship the containers back to China empty than to have it circulate the US to carry and ship items out of the US. This means if you want to ship items around the world, you’d have a hard time getting a container because they’re mostly back in China or you’d have to pay a high price for it.